Problem

A US-based commercial equipment manufacturer was preparing for a product launch, but their existing supplier was struggling to provide the required parts.

Solution

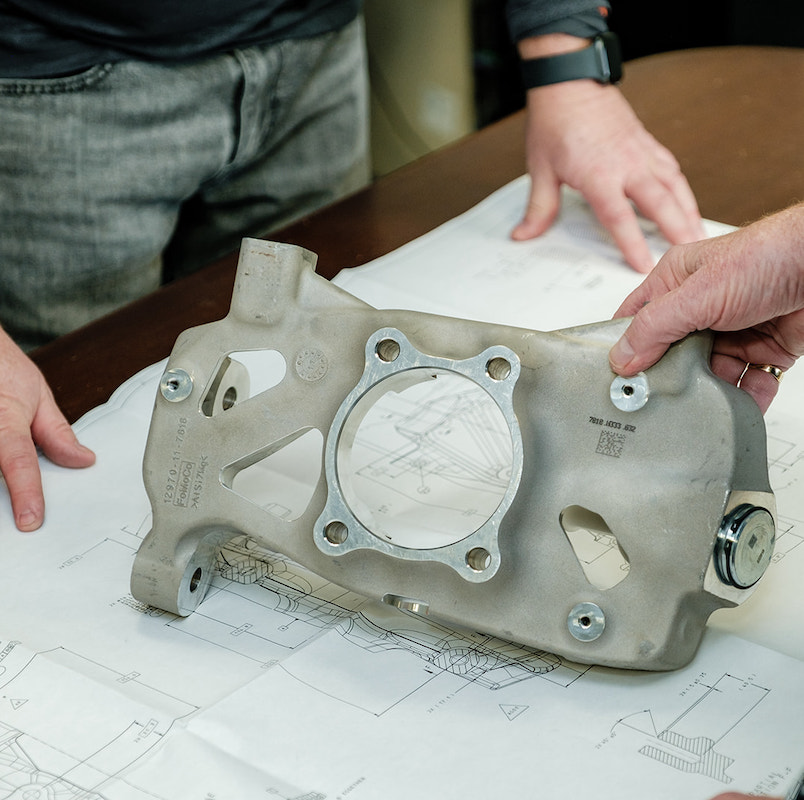

Ramsden stepped in to produce the required finished aluminum castings, as well as providing some of the sub-assembly and external processing.

Impact

In partnership with Ramsden, this customer was able to maintain business continuity and achieve its product launch objectives.

When customers come to Ramsden for low pressure and permanent mold aluminum casting services, they typically require more than high-quality parts – what they are really seeking is a partner that can provide solutions to meet their overall business objectives.

Recently, a US-based commercial equipment manufacturer sought our help to produce a family of five aluminum parts critical to a new product launch. Their existing supplier was unable to meet the quality and delivery requirements, so this customer turned to Ramsden for solutions.

We were able to step in on short notice to meet this customer’s needs and allow their product launch to proceed as planned. Three factors contributed to the success of this project:

1. Focus on customer needs

When this customer approached us for help, we went beyond the technical casting requirements to also fully understand their business needs. Because we understood their product launch objectives and timeline, we adjusted our priorities and acted nimbly to deliver their required parts on time.

Our adaptability allowed our customer to avoid costly delays and maintain business continuity so they could meet the needs of their end customers.

2. Direct access to our team

This customer was able to pick up the phone and speak directly with the technical and business leaders at Ramsden. As a result, we were able to discuss technical requirements, coordinate plans, and come up with solutions more efficiently.

We eliminate excessive bureaucracy by ensuring our customers have direct access to the experts and decision makers on our team.

3. Value-added services

Given the complexity of this customer’s supply chain, we provided a number of value-added services to help them boost efficiency and reduce lead times. In addition to producing the finished aluminum castings, we also arranged machining for the parts, coordinated with another partner to carry out sub-assembly work, and shipped parts directly to a sub-supplier.

By relying on our supply chain expertise and collaborating with our network of partners, our customer was able to increase the efficiency of the overall production of its new product.

Partnering to achieve your business goals

In the aluminum casting industry, customers expect high-quality parts delivered on time and in line with their specifications. At Ramsden, we consider this to be the bare minimum. We strive to set ourselves apart by going beyond the technical requirements to help our customers meet their overall business objectives.

This means acting nimbly when required to align with our customers’ priorities, providing customers with direct access to our team, and delivering value-added services to boost supply chain efficiency. With this approach, our customers get a partner, not just a supplier.

If you’re looking for a trusted partner to keep your business running smoothly with high-quality low pressure and permanent mold aluminum castings, please contact us.